In the manufacturing industry, packaging is crucial for ensuring product integrity, enhancing brand image, and improving customer satisfaction. However, traditional packaging processes can be inefficient and prone to errors. Digital solutions are transforming how packaging lines operate, boosting efficiency, and reducing downtime.

Digital Solutions in Packaging

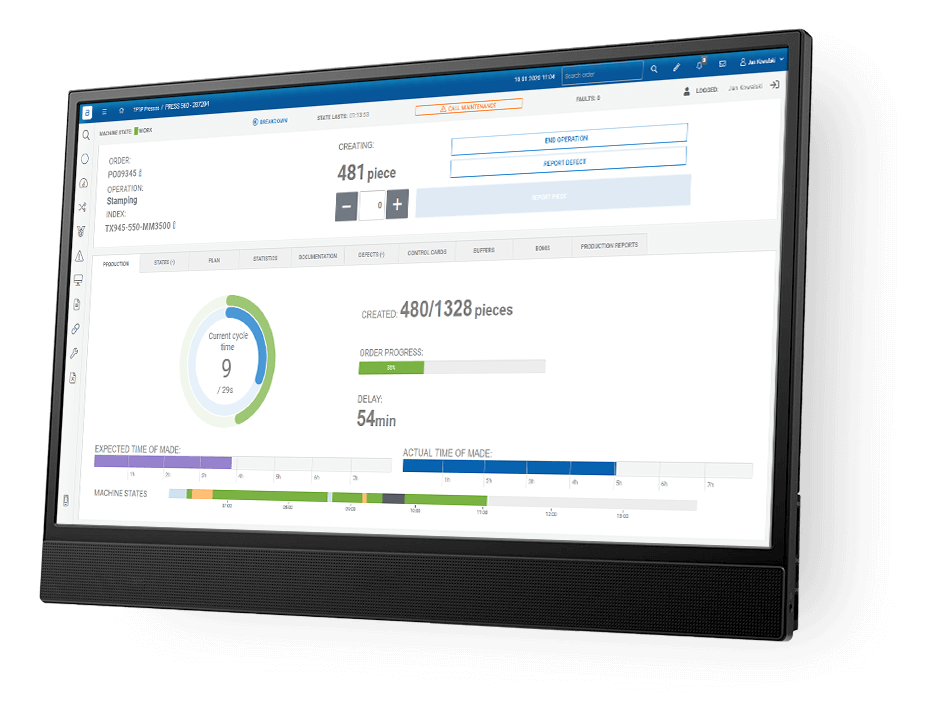

Digital solutions like Manufacturing Execution Systems (MES) and Overall Equipment Effectiveness (OEE) monitoring are revolutionising packaging in the manufacturing industry. These systems collect real-time data from machines and provide work instructions that help streamline operations and enhance productivity.

System realizacji produkcji (MES)

MES is a comprehensive system that manages and monitors the entire production process. It integrates with various machines on the production floor to gather data, track performance, and ensure quality control. Implementing MES offers several benefits:

-

- Improve production scheduling: MES helps optimise production schedules, ensuring efficient use of resources and meeting production targets.

-

- Enhance quality control: Real-time monitoring of the production process ensures that quality standards are maintained, reducing the risk of defects.

-

- Increase traceability: MES provides detailed records of the production process, essential for compliance with industry regulations.

Overall Equipment Effectiveness (OEE) Monitoring

OEE is a key performance indicator measuring the efficiency of manufacturing processes, considering factors like machine availability, performance, and product quality. Implementing OEE monitoring systems can significantly improve packaging line efficiency by:

-

- Real-time data collection: OEE systems collect data directly from packaging machines, providing real-time insights into machine performance and identifying areas for improvement.

-

- Downtime analysis: Analysing the causes of downtime allows manufacturers to implement targeted strategies to reduce machine stoppages and improve productivity.

-

- Performance tracking: OEE systems track the performance of individual machines and entire production lines, helping manufacturers identify bottlenecks and optimise processes.

Case Study: ANT Solutions’ Implementation

A practical example of digital solutions in packaging is ANT Solutions’ implementation of OEE monitoring across multiple packaging lines. This involved:

-

- Monitoring OEE for seven blister packaging lines.

-

- Integration with SAP for seamless data flow and process optimisation.

-

- Installation of operator panels and large displays for real-time monitoring.

As a result, the manufacturer saw a significant increase in OEE, reduced micro-downtime, and decreased mean time to repair (MTTR). Specifically, OEE increased by 12% in one year, and micro-downtime was reduced by 27%.

Benefits of Digital Solutions in Packaging

The adoption of digital solutions in packaging offers several benefits:

-

- Increased Efficiency: Real-time monitoring and data analysis help identify inefficiencies and optimise packaging processes.

-

- Reduced Downtime: Understanding and addressing the causes of downtime keeps packaging lines running smoothly.

-

- Improved Quality Control: Digital solutions ensure that packaging meets quality standards, reducing the risk of defects and recalls.

-

- Enhanced Decision-Making: Access to real-time data enables better decision-making and more effective action planning.

Addressing Workforce Challenges

Digital solutions are also vital in addressing workforce challenges such as staff shortages and high turnover rates. By optimising packaging processes, manufacturers can:

-

- Increase the efficiency of packaging lines.

-

- Improve quality control processes involving both equipment and human oversight.

-

- Enhance collaboration through routine meetings and action planning involving operators, supervisors, maintenance teams, and continuous improvement groups.

As noted by Servier, “Packaging lines are monitored by the ANT system, which controls performance and analyses the causes of downtime. Packaging process improvement involves routine meetings and action planning by various groups involved in the production process. In the face of challenges such as staff shortages and turnover, Servier focuses on ensuring the quality of its manufacturing processes to provide the best products for its patients.”

Wniosek

Optimising packaging processes in the manufacturing industry through digital solutions is essential in today’s competitive landscape. Systems like MES and OEE monitoring provide valuable insights that help manufacturers enhance efficiency, reduce downtime, and maintain high-quality standards. By embracing these digital technologies, manufacturers can achieve greater productivity and deliver better products to their customers.

Powiązane artykuły

Co to jest OEE, OOE i TEEP w produkcji?

OEE, OOE i TEEP to wskaźniki wykorzystywane do pomiaru efektywności sprzętu produkcyjnego. Każdy z nich ma nieco inny cel, ale wszystkie są podobne.

Monitorowanie wydajności OEE

Monitorowanie wydajności (OEE) Podłącz i zbieraj dane z maszyn. Zaplanuj demonstrację. Kluczowe korzyści Wzrost OEE ✔️ krótsze przestoje ✔️ szybsza produkcja

Audyt przedwdrożeniowy systemu MES - jak go przeprowadzić?

Wdrożenie systemu MES jest złożonym i kosztownym procesem, który wymaga starannego planowania i przygotowania. Kluczowym krokiem jest przeprowadzenie