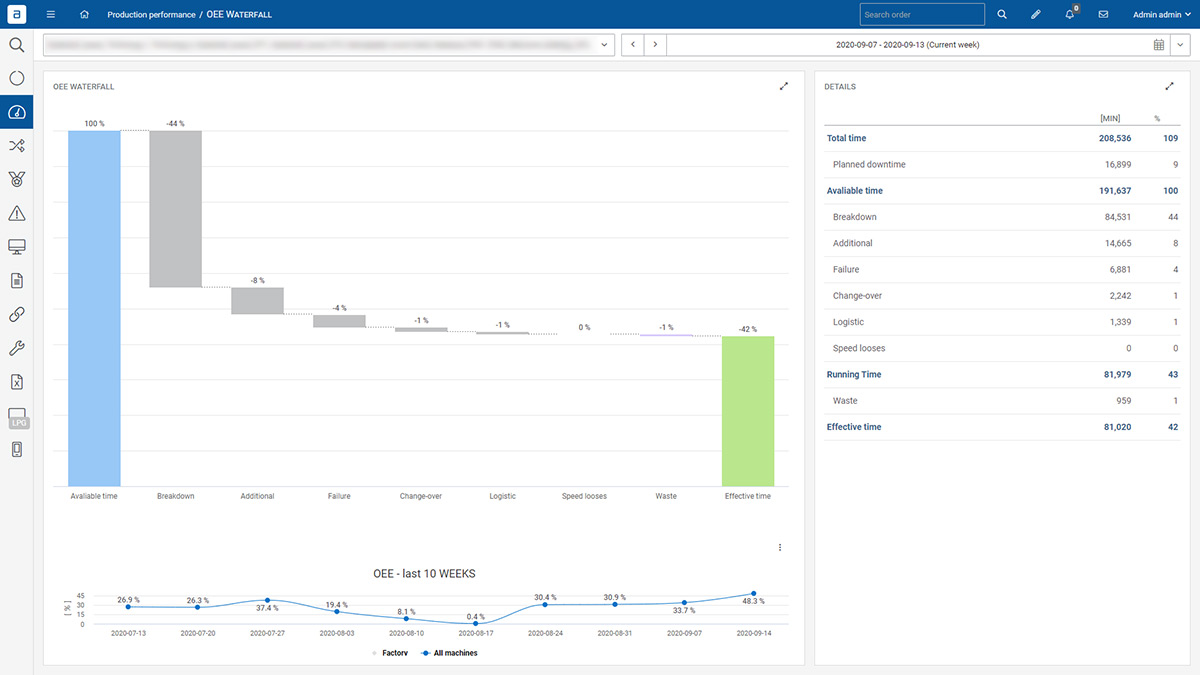

- Overall Equipment Effectiveness (OEE) is low due to one or more of the following factors: availability, performance, and quality.

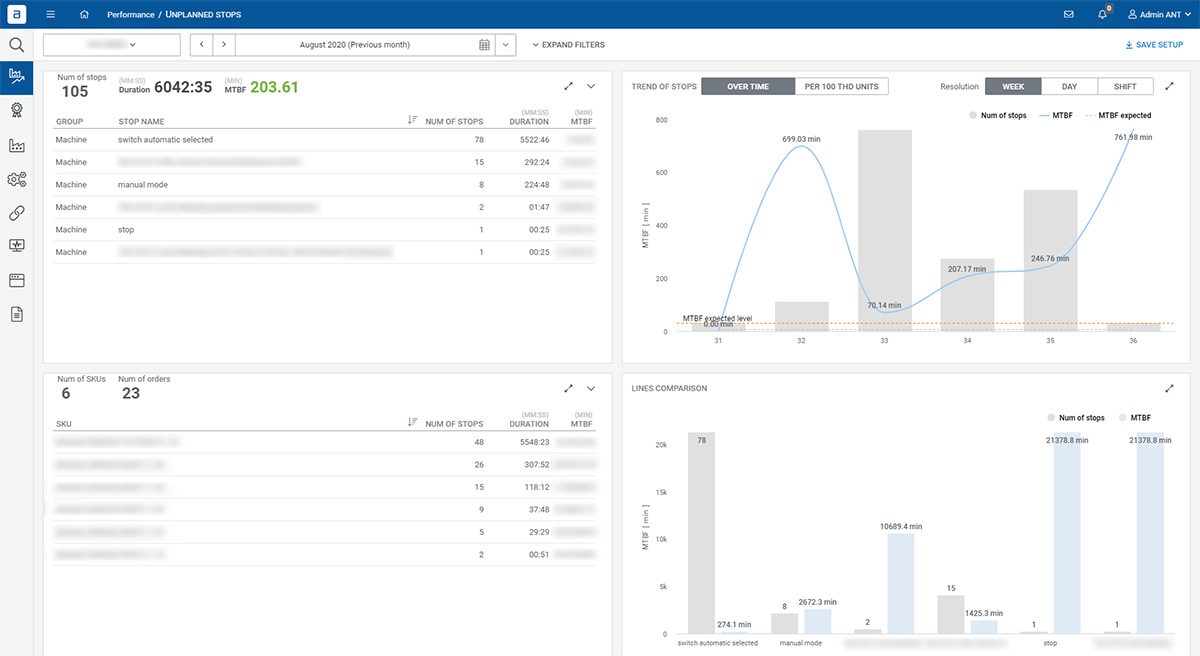

- Availability may be low due to unplanned downtime, downtime duration, and lack of improvement in KPIs. Unplanned downtime can be caused by reactive maintenance, failing to gather information about downtime, slow reaction times by maintenance services, and lack of updated information.

- Unplanned downtime: This can be caused by equipment failures, power outages, and other disruptions. Unplanned downtime is a major contributor to low OEE because it reduces the amount of time that the equipment is available to produce good products.

The OEE is the result of three factors, these being availability, performance, and quality. It’s no secret that improving just one of the factors immediately increases the value of the OEE and therefore brings about benefits for the business in its entirety. In the manufacturing sector achieving optimum results across all three areas is key to operating a successful line since they all individually contribute to the viability of the product or service and the profitability.

Disponibilità - per far sì che il vostro tempo conti davvero

This factor essentially encompasses any events that have the potential to bring any planned production to a halt for a sustained time. Though downtime is a necessity in the manufacturing industry, it should be kept to a minimum to minimize losses and ensure maximum productivity. There are three main ways that this can impact the overall OEE.

1. Troppi tempi di inattività non pianificati

This is often due to reactive maintenance. However, failing to gather information about the real reasons for downtime can also prevent improvements from being made in this regard.

2. Downtime that drags on for a sustained period

I tempi di reazione lenti da parte dei servizi di manutenzione, la chiamata manuale degli interventi di manutenzione, la mancata raccolta dello storico di funzionamento delle macchine o la mancanza di informazioni aggiornate sono tra le ragioni principali.

3. Nessuna misurazione e miglioramento dei KPI".

MTTR (mean time to recovery), MTBF (mean time between failure), and MTTF (mean time to failure) all have a part to play in both measuring and improving key performance indicators.

ANT’s endorsed approach to availability is the Andon maintenance module. The Andon maintenance module seeks to reduce such issues by compiling the history of repair reports and using the most recent failures as hints, measuring maintenance reaction times, providing relevant maintenance services along with the causes of downtime, and taking KPI measurements (MMTR, MTBF, MTTF) regularly.

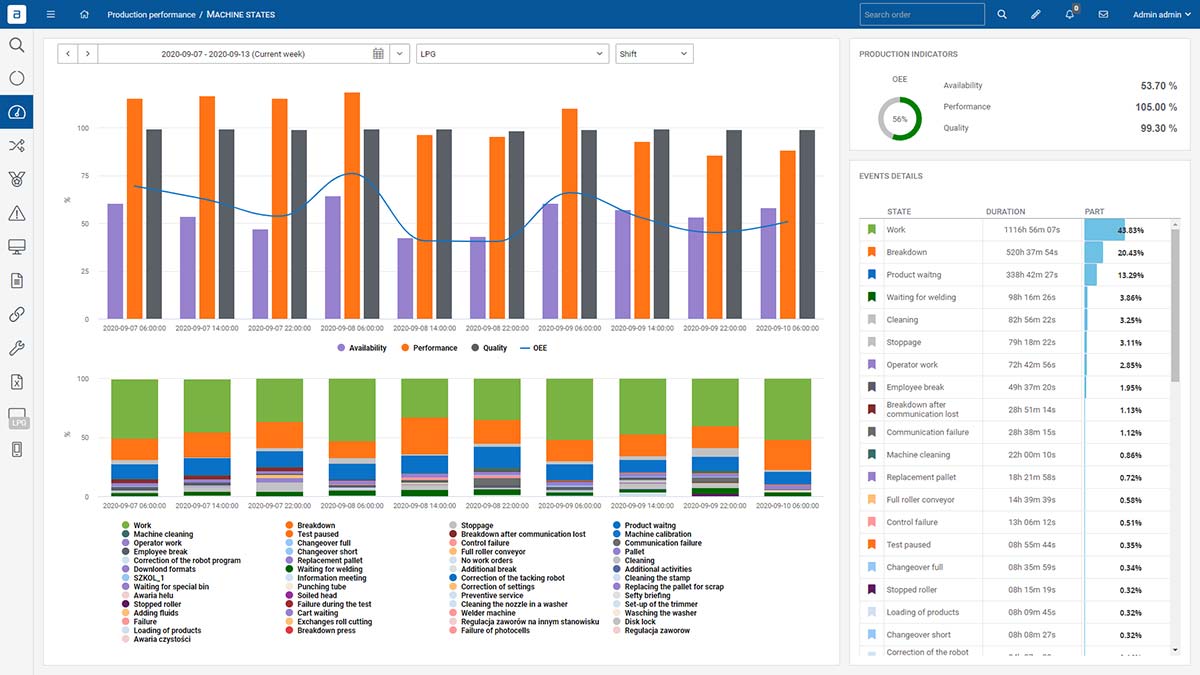

Prestazioni: la capacità di individuare qualsiasi potenziale ostacolo sulla strada.

The performance takes into account anything that causes the manufacturing process to run at less than the maximum possible speed when it is running (including both Slow Cycles and Small Stops).

However, it’s important to highlight that this particular factor is not associated with units produced, but rather with the equipment or technology used to run the manufacturing line itself. Here, adjustments can be made to boost the efficiency and capability of the line in question.

4. Ciclo lento

Ciò è generalmente associato a una mancanza di monitoraggio in termini di tempi di ciclo reali, alla mancata automazione, alla mancanza di programmazione delle attività o a un numero eccessivo di micro-arresti in un determinato periodo di tempo.

5. Lancio lungo della produzione

Multiple changeovers are among the most common culprits in these cases, although manual communication with laboratories or quality control departments can also impact production launches.

6. Mancanza di formazione degli operatori

Ciò può essere dovuto alla mancanza di istruzioni digitali passo-passo per gli operatori, ai tempi eccessivi di inserimento o alla mancanza di trasparenza in termini di produzione e obiettivi di produzione.

To combat these three reasons for limited performance, ANT has created Digital Documentation and Paperless modules. These enable you and your manufacturing team to display digital information to the operators, categorize documentation such as changeovers and quality controls, guide operators through production and changeovers using step-by-step activities, and automate communication with the laboratory.

It is hoped that this tool will enable you to make your line more efficient and, as a result, boost your overall productivity. Although it may seem cliché, it’s often true that the key is in the finer details, and although a micro stop may seem insignificant, a micro stop module is designed to open your eyes to their potential impact.

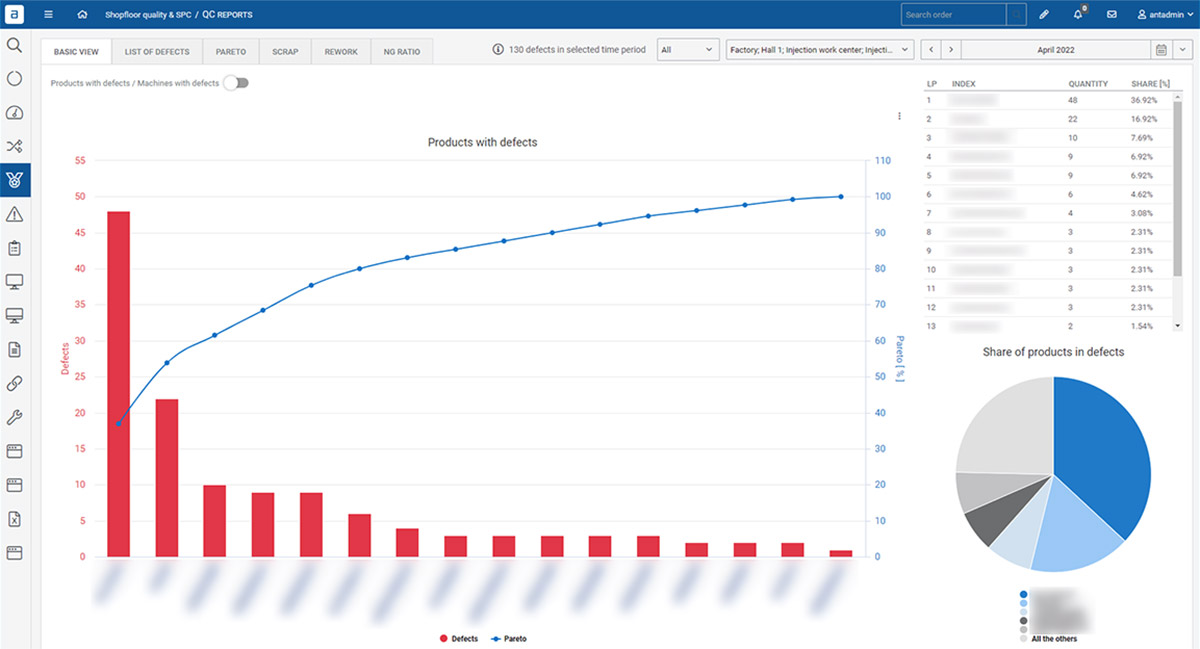

Qualità - un'ispezione ravvicinata e personale dei dettagli più fini

La qualità, invece, tiene conto dei pezzi prodotti che non soddisfano gli standard di qualità, compresi quelli che devono essere rilavorati. In altre parole, è un mezzo per misurare la resa del processo della linea e come questa sia influenzata da difetti o modifiche.

7. Troppi difetti

A lack of analysis in defect production stands out as the most common cause, although cyclic activity lists for operators can also influence the number of defects detected.

8. Nessuna convalida dei materiali/strumenti/parametri di processo utilizzati prima di avviare la produzione.

Cross-checks with used materials batches in the ERP system used material codes in BOM lists are essential in this case, however, it is also crucial to ensure that the machine setpoints (recipes) are correct (manually by the Operator or automatically by ANT system & PLC)

9. Lriconoscimento di un processo instabile

This is commonly associated with a Lack of SPC diagrams & control charts & condition-based monitoring. That said, failure to implement automatic counting of how many cycles the tool has made (tool life cycle monitoring and regeneration plan) can also influence late recognition.

ANT seeks to remedy these issues through the launch of its Quality Inspections module, which helps operators and other line management staff to make more informed decisions, by providing them with automated feedback and detailed instructions. The module is also capable of producing a series of quality reports covering specific aspects such as defects.

Ragioni generali che influenzano l'OEE

10. Equazione OEE

It’s worth bearing in mind that the use of manual calculation methods is often inefficient, many companies also tackle the OEE calculation rather unobjectively or simply fail to implement it altogether

11. No tools and no plan for what to improve

A lack of tools to compare shifts, operators, machines, lines, and items, no clear method that determines how the gathered data should be used, or a lack of trend analysis also leads to issues in terms of production efficiency.

12. Dati inaffidabili

Questo è un altro nemico dell'efficienza produttiva, spesso causato dall'insistenza sull'uso della documentazione cartacea, dai ritardi nella trasmissione delle informazioni e dalla raccolta dei dati in tempo reale da parte delle macchine.

Of course, not all the reasons for low OEE can be attributed to these three main factors. However, our real-time notifications can help to minimize the impact of any issues that you may experience. Our system is also customizable so you can calculate your OEE in a way that works for your business, as opposed to using a standard, one-size-fits-all program.

The real value of OEE can’t be underestimated in manufacturing processes and improving quality, availability, and performance is essential, as difficult as it may seem. The way forward is to make decisions based on numbers instead of personal opinions.

Se avete bisogno di ulteriore assistenza per misurare e migliorare l'OEE della vostra azienda, non esitate a contattare il team di ANT per ricevere aiuto e consulenza professionale. Saremo lieti di discutere i moduli più adatti alle vostre esigenze e ai vostri requisiti specifici.

Key Takeaways:

- Master the three pillars of OEE: Minimize downtime, optimize production speed, and minimize defects.

- Embrace data-driven decision-making: Leverage automated data collection and analysis to gain valuable insights and continuously improve OEE.

- Move beyond manual calculations: Utilize automated methods for accurate and efficient OEE calculation.

- Achieve superior operational performance: By implementing these strategies, manufacturers can significantly enhance OEE and gain a competitive edge.

Prodotti in questo articolo

Monitoraggio delle prestazioni OEE

Monitoraggio delle prestazioni (OEE) Collegatevi e raccogliete dati dalle vostre macchine. Programmate una demo Si sono fidati di noi: Benefici principali Aumento dell'OEE ✔️ tempi di inattività più brevi ✔️ produzione più rapida

Sistema MES - Sistema di esecuzione della produzione - Soluzioni ANT

Sistema MES - Manufacturing Execution System 0 % aumento dei tempi operativi 0 % riduzione della quantità di difetti 0 % riduzione del consumo di materiali 0 % tempo di cambio

Monitoraggio delle microfermate

MIcro stopsmonitoring Stop the stops The most effective system for FMCG for monitoring production rates and downtime Schedule a Demo Addressing Micro Stops and Downtimes