What is Effective Production Monitoring?

Effective production monitoring refers to the systematic tracking, analysis, and management of various aspects of the manufacturing process to optimise efficiency, reduce costs, and improve quality. It involves utilising technology, data analytics, and human expertise to gain real-time insights into production activities, enabling prompt decision-making and continuous improvement. Effective production monitoring is characterised by several key components.

Key Components of Effective Production Monitoring

Real-Time Data Collection

Effective production monitoring is rooted in the collection of real-time data. This involves the use of sensors, machines equipped with IoT (Internet of Things) technology, and other data collection tools to gather continuous, real-time data on various aspects of the production process.

Comprehensive Analysis

The collected data needs to be analysed to extract meaningful insights. This includes identifying patterns, trends, and anomalies that can indicate areas of inefficiency, potential breakdowns, or opportunities for optimisation.

Actionable Insights

Effective monitoring provides actionable insights. It’s not just about collecting and analysing data but using those insights to make informed decisions that improve efficiency, reduce downtime, and enhance product quality.

Integration with Other Systems

A comprehensive monitoring system is integrated with other enterprise systems like ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and SCM (Supply Chain Management) to ensure seamless data flow and holistic decision-making.

Flexibility and Scalability

An effective system is flexible and scalable, able to adapt to the changing needs of the production environment and grow with the business. It should be customisable to fit the specific requirements of different industries and production scales.

User-Friendly Interface

Ease of use is critical. A user-friendly interface ensures that operators, managers, and other stakeholders can easily access, understand, and utilise the data and insights provided by the monitoring system.

How to Optimise Processes with Data?

Data Analysis

Monitoring systems for production processes, such as MES, offer the capability to gather and analyse vast amounts of real-time data. Collecting data from different stages of the production process allows for the identification of areas for improvement and forecasting trends and changes, essential for making informed business decisions.

Process Automation

Automation is a key element that enables companies to focus on the strategic aspects of their operations, leaving routine tasks to machines and algorithms. From monitoring machine parameters and production efficiency to tracking energy consumption and managing warehouses – automation increases efficiency and reduces costs.

Why Invest in IT Tools in Production?

Enhancing Competitiveness

In the era of digitisation and growing competition, investing in advanced IT systems is not just beneficial but essential. Companies utilising tools like MES, EMS, CMMS, or WMS can quickly adapt their operations to changing market conditions, enhancing their competitiveness.

Innovation and Growth

The implementation of modern IT solutions fosters innovation and allows for developing unique competencies. Companies investing in technology often become innovation leaders in their industries, leading to increased market share and profits.

Tools used for production process monitoring

Various tools are used for production process monitoring, both software and hardware. The most popular ones include:

-

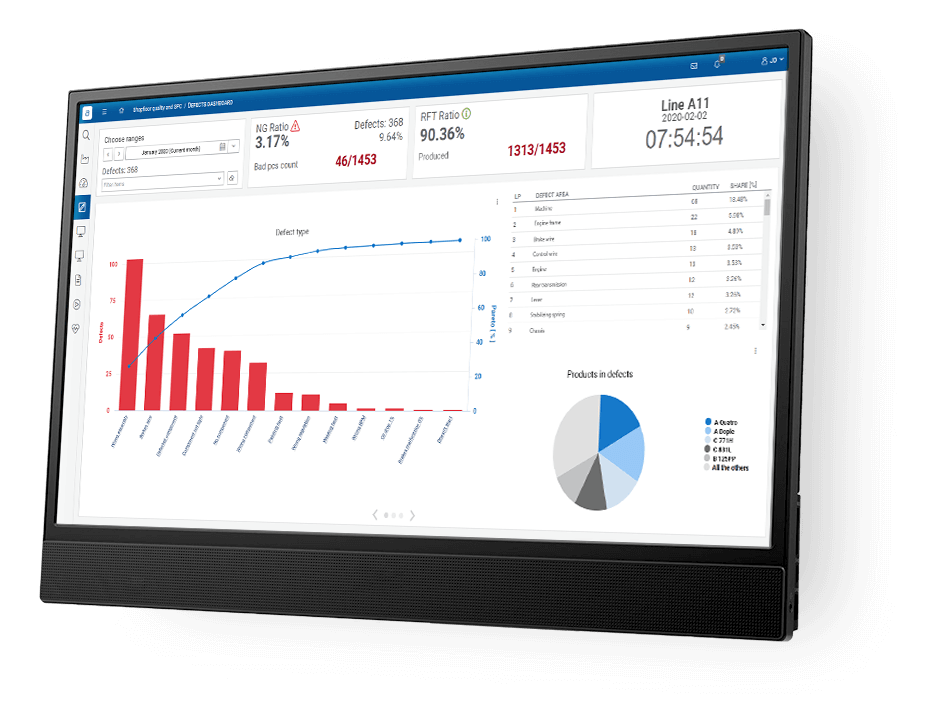

- MES (Manufacturing Execution System) – used for managing and monitoring production in real time. MES systems allow for collecting data from production machines and equipment, and then analyzing and reporting it.

-

- CMMS (Computerized Maintenance Management System) – used for maintenance management. CMMS systems allow for tracking the status of machines and equipment, planning inspections and repairs, and recording the history of maintenance work.

-

- EMS (Energy Management System) – used for monitoring energy consumption in the plant. EMS systems allow for identifying areas where energy can be saved.

-

- WMS (Warehouse Management System) – used for warehouse management. WMS systems allow for tracking inventory levels, planning deliveries and shipments, and quality control of products.

How manufacturing systems help to monitor production process?

Production process monitoring requires collecting data from various sources. Data can be collected from production machines and equipment, sensors, counters, as well as ERP and CRM systems.

Standard communication protocols are used to collect data from production machines and equipment, such as OPC, Modbus TCP, Siemens TCP, Ethernet/IP, ADS, PROFINET, EtherCAT. In the case of older devices or when it is not possible to connect to the PLC controller, it is possible to duplicate signals and transmit them via Modbus TCP.

Different technologies are used to collect data from sensors and counters, such as Wi-Fi, Bluetooth, Ethernet. Data can also be collected from ERP and CRM systems using API interfaces.

Customer benefits of production process monitoring

Production process monitoring with modern IT systems can bring companies many benefits, including:

-

- Increased efficiency – process monitoring allows for identifying areas where efficiency can be improved.

-

- Minimisation of losses – process monitoring allows for detecting and preventing material, production, and financial losses.

-

- Improved quality – process monitoring helps ensure high-quality products and services.

-

- Increased safety – process monitoring helps improve the safety of employees and the plant.

Real live examples of benefits from production process monitoring

Here are a few practical examples of the benefits that companies have achieved through production process monitoring:

-

- A furniture manufacturer reduced energy consumption by 6%, which resulted in savings of PLN 250,000 per year.

-

- An electronics manufacturer generated new business worth PLN 710,000 per month by monitoring micro-stops and increasing line availability.

-

- A food manufacturer reduced material waste by 15%, which resulted in savings of USD 1,000 per day.

-

- A car manufacturer introduced a Just In Time system and reduced the cost of finished goods inventory by 90%.

-

- A clothing manufacturer reduced the time spent on reporting by 90%.

- A toy manufacturer reduced the cost associated with lack of material demand monitoring by 70%.

In addition to financial benefits, production process monitoring can also bring companies other benefits, such as:

-

- Improved flexibility – process monitoring allows for quick response to changes in demand for products or services. By monitoring the use of materials and energy, companies can adapt their production to changing customer needs.

-

- Increased competitiveness – process monitoring allows for cost reduction and quality improvement, which can lead to increased competitiveness of the company.

-

- Improved worker safety – process monitoring allows for identification and elimination of hazards to worker safety. By monitoring working conditions, companies can provide a safe working environment for their employees.

-

- Increased employee engagement – process monitoring can be used to motivate employees and increase their engagement in work. By providing employees with information about their performance, companies can help them identify areas where they can improve.

It is important that the process monitoring system is tailored to the needs of the company. The specific production, the size of the company, and the available resources should be taken into account.

When choosing a process monitoring system, the following factors should be considered:

-

- Functionality – the system should provide all the necessary functions for monitoring production processes.

-

- Ease of use – the system should be easy to operate and configure.

-

- Cost – the cost of the system should be tailored to the company’s budget.

Companies that want to implement a process monitoring system should seek the help of specialists. Specialists will help in the selection of the appropriate system, as well as in its implementation and configuration.

Production process monitoring is a key element of production management. By using the right tools and technologies, companies can achieve significant business benefits, both financial and non-financial.

Trends in production process monitoring

The development of artificial intelligence (AI) and machine learning (ML) technologies has a significant impact on production process monitoring. AI and ML can be used to automate monitoring processes, detect anomalies, and take corrective actions.

Examples of solutions using production process monitoring in different industries

Production process monitoring is used in various industries, such as:

-

- Heavy industry – process monitoring can be used to improve efficiency and quality of production in heavy industry.

-

- Food industry – process monitoring can be used to ensure food safety in the food industry.

-

- Pharmaceutical industry – process monitoring can be used to ensure the quality of pharmaceutical products.

-

- Textile industry – process monitoring can be used to improve the quality of fabrics in the textile industry.

-

- Electronics industry – process monitoring can be used to improve production efficiency in the electronics industry.

Conclusion

Monitoring the production process using advanced IT tools is the key to increasing efficiency, reducing costs, and improving product quality. Systems like MES, EMS, CMMS, and WMS lay the foundation for modern production, enabling companies to ascend to a higher level of management and control over their operations.

Today’s market is more competitive than ever, and companies are seeking solutions that will give them a competitive edge. Utilising IT solutions in the production process is not just a trend but a necessity that determines the future of every manufacturing enterprise.

The application of informational technology in production opens the doors to a world of higher efficiency, better quality, reduced losses, and increased profits. Don’t wait – invest in advanced tools for monitoring the production process and start unlocking the full potential of your business today!

Products in this Article

Manufacturing Operations Management System (MOM)

Manufacturing Operations Management System (MOM) The most complete manufacturing solution with full support for operations management and a link between industrial automation and business operations

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

Smart Machine

Smart machine A comprehensive solution for management, diagnostics, monitoring and control of the production line. Schedule a Demo They Trusted Us: Make sure you have