Production management and consistent pursuit of high quality of products – irrespective of the industrial sector or final goods – is closely linked to the improvement of production processes and modifying recipes according to which the final products are manufactured. A key or fundamental issue in this respect is to ensure the proper control of recipes and therefore the implementation of automated recipe management solutions, which has a significant impact on reducing changeover time, reducing human error, which directly translates into increased line productivity and improved process control. What should be considered when choosing the right software?

When choosing the right software, you should pay special attention to whether it includes a recipe manager. While there are many Manufacturing execution systems available on the market, not all of them offer the possibility of recipe management.

These systems should provide the following functions:

- recipe management,

- tracking of recipe versions,

- selecting, assigning and automatic distribution of recipe on equipment level.

The lack of above mention functionalities entails serious consequences, makes it difficult to control machine settings, ensure high-quality products and reduce the amount of rejects, which reduces the efficiency of the entire line.

Another, if not the most important argument for the introduction of automated recipe management systems is the requirement in some industries to trace products together with the recipe according to which they are made, in order to ensure high quality and to meet the high compliance requirements of quality standards. This is particularly important in industries such as pharmacy, food production, electronics and automotive.

Recipe Manager – The ANT module for supervising and managing recipes

When considering how to automate the sending of recipes to devices, it is worth paying attention to the capabilities of the ANT system. It provides a fully functional tool for recipe management and module to automatically recipe distribution, which has the following functionalities:

- display and view a complete list of recipes with expected setpoints for the individual process parameters,

- view the contents of individual selected recipe,

- modify recipe structure and data,

- tracking changes – with comprehensive information on who made changes and when,

- different levels of authorization to release recipe for production,

- automatic or manual sending of recipes to all or individual machines/stations.

Recipe intended for a device usually contain the following data:

- machine setpoints,

- process setpoints – information strictly related to production process of individual product (item),

- routing,

- bill of materials (BOM),

- machine program.

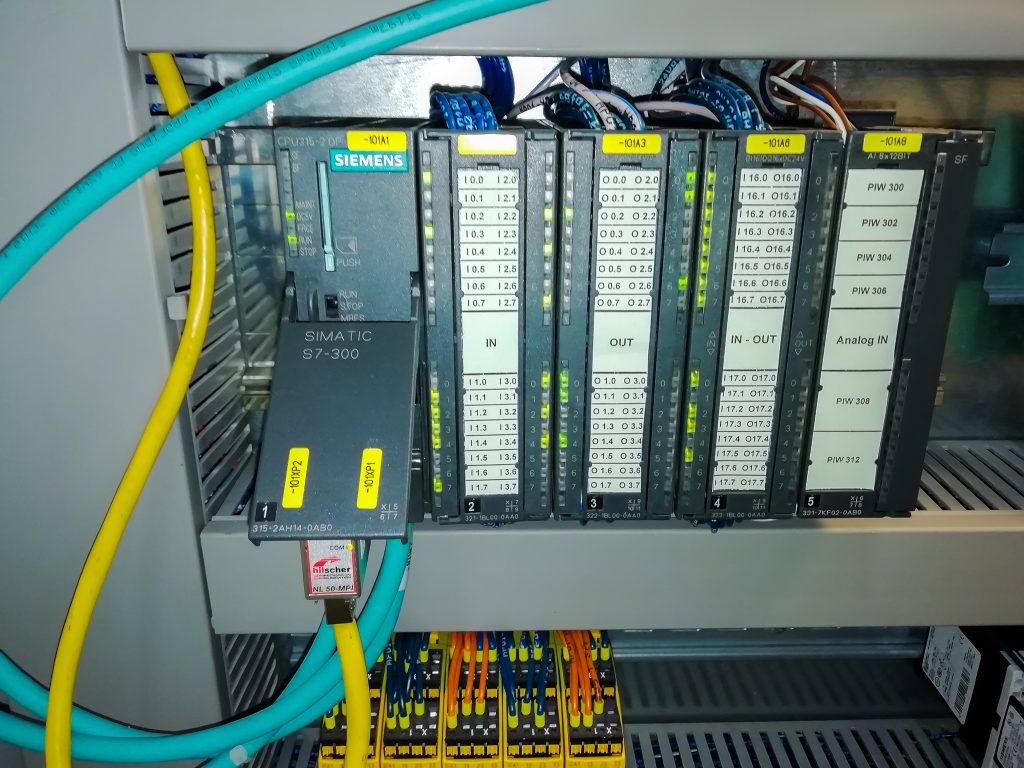

Communication between programmable logic controller (PLC) and ANT system

ANT supports almost all communication protocols used in industry. These include, for example:

- Modbus,

- Profibus,

- Profinet,

- Ethernet/IP,

- OPC UA.

If there are no special customer requirements – or other relevant reasons – communication via Ethernet and TCP protocol is the optimal solution.

The ANT solution is based on TCP communication protocol, predefined and structured telegrams, that are designed for fast integration on BBS Automation lines. It can be used as a basis for developing other custom protocols used by other PLC and machine vendors for easy integration into the SM system. A standard ANT telegram library consists of various predefined telegrams, for example: order management, T&T, recipes, order status, machine alarms and diagnostics.

The dedicated tool “Telegram Manger” allows the engineer to freely adjust the data content of individual telegrams. The integrated generator significantly reduces the implementation time for telegrams on the PLC side, by generating PLC data blocks or source files ready to import to PLC.

Combination of functions of recipe manager and telegram manager, in practice, gives a powerful tool for centralizing and coordinating of recipe and data flows between the device, controller, and ANT system managed by the operator.

PLC and ANT system – how does it look like in practice?

In the past, the implementation solved a problem for one client who was using software provided by four different vendors. They had different communication protocols. Ultimately, ANT was able to move the data from the four providers into one common, standardized communication that was carried out over the ANT TCP protocol. This proves that ANT has exceptional flexibility in the context of data exchange with production lines. This is a particularly important feature when an entity uses non-standard technological solutions or tries to organize the somewhat chaotic operation of several systems simultaneously. In such a situation, ANT acts as an overlay, so to speak, centralizing the functioning of the several other systems.

There are other examples of specialized implementations – where one standard communication protocol had already been implemented. Based on the protocol, ANT has adapted its own protocol to the existing one, thus ensuring full compatibility of data exchange. In practice, this meant an extremely valuable opportunity to read and write all the data from and to the PLC’s line.

How does the distribution of recipe take place?

A recipe contains all machine and process settings, can be sent to the PLC controller manually by the operator or automatically:

- when starting a new order (during the changeover procedure),

- when the PLC controller requests a specific formula,

- with a new order with the status “started” and recognized by the PLC,

- in the event of the loss of a recipe due to, for example, a power failure.

Alternatively, for older machines where the communication does not allow the sending of setpoints, the system displays a list of expected setpoints on the operator’s control panel, and the setpoints are set manually by the operator on the machine’s HMI. Next, ANT Smart Factory validates whether the values in the PLC responsible for the setpoints are correct, and then it releases the machine for production.

What are the benefits of implementing ANT?

The main advantage of implementing recipe and task management systems including automatic recipe distribution is to facilitate the work of plant operators, production managers and engineers responsible for maintenance of the production line. This also reduces the risk of human error. This is thanks to a reduction in the time needed to start production after changeover and automation when it comes to selecting recipes. The benefits also include centralized storage and management of recipe content as well as reduced equipment configuration requirements.

Products in this Article

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

Machine Connectivity

Machine Connectivity Machine Connectivity is responsible for communication with machine’s PLC and devices, providing the real measurement from the machine for acquisition, processing and administration

Smart Machine

Smart machine A comprehensive solution for management, diagnostics, monitoring and control of the production line. Schedule a Demo They Trusted Us: Make sure you have