Digitalization has firmly established itself in everyday production processes, regardless of the industry. Nevertheless, habits remain from the days before widespread digitalization, traditional solutions not going hand in hand with business efficiency. Paper is an example of this – it is still common when creating documentation used on the shop floor. Creating a paperless manufacturing environment will ensure that you never go back to paper documentation again.

The implementation of an MES – and thus creating a paperless manufacturing environment – translates into more efficient manufacturing processes and analytics.

Creating documents in a company covers a unique spectrum of tasks, as it involves such processes as:

• data management

• general distribution

• document archiving

• updating of rules and regulations

In this context, filing paper documentation is both time-consuming and costly. It requires more human resources and regular purchase of base material. This is compounded by the growing problem of how to store the catalogues, binders, lists and all the other products, collected over the years, that constitute the archive of the company. In the case of a claim, finding the right documentation can be difficult or impossible.

A paperless system instead of paper-based documentation workflow in a company

In order to create paperless environments, companies are gradually migrating data from paper records to their own IT systems. This is a time-consuming process. The wrong choice of paperless solution, inaccurate communication in relation to the tasks set, technical deficiencies – all of these can contribute to an incorrect transfer of resources. As a result, although formally theoretical digitalization and elimination of paper documentation are taking place, in practice things like human error can lead to delays and prolonged processes.

This is why it is so important to choose the right technology and system to ensure the migration of data to shop floor software in a non-invasive way. This can be ensured by the ANT solution: paperless modules for digital documentation and paperless manufacturing.

Paper documentation: problem and solution

The answer to this question in the vast majority of companies – regardless of their business profile – is similar: yes, excess paper is harmful. It translates into higher business costs, requires people to handle tasks and is sometimes difficult in terms of analytics.

If you look at the use of paper in the production process alone – thus ignoring for example administration – you can see how many documents have mandatory status. These include not only job and assembly documentation but also quality-related sheets, maintenance schedules, OHS instructions and system changeover instructions.

Paper documentation in the production process also presents a risk of inappropriate records – mainly a lack of updating. While with paperless manufacturing software it is easier to make sure that this process is carried out, the instructions hanging next to the machine are sometimes forgotten and ignored. Incorrect documentation used in the production process results in a large number of quality issues. In addition, in the case of a multi-stage production or a division of tasks with a large number of diverse positions, the control of paper documents is difficult.

How to move paper documentation workflow into paperless manufacturing software?

The ANT Digital Documentation Module technology is the solution. It is a module that demonstrates that the traditional understanding and perception of documents can be digital but still retain its natural character.

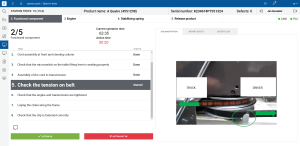

The solution, which is enjoying considerable popularity, is based on the preparation of a special operator’s control panel. This software for production allows you to display documentation files in PDF format; in addition, it provides a display of videos and photos for a given production order, the type of operation or the type of machine. What the operator gets in practice, therefore, is a much broader package of resources: not just the paper documentation itself – e.g. a manual – but a full package of multimedia perfectly illustrating the individual processes.

Also notable is how the digital documentation is cataloged. In most cases, this is done in terms of user and departmental permissions. You can therefore ensure that access to specific content is available to people with specific needs or levels. This also makes it easier to ensure that the operator can check all the documents and instructions necessary for the current production order.

Another benefit of the software for production is the care for constant updating of documents and the form of their presentation. If the data has been overwritten and contains new content that the user needs to be familiar with, this is displayed as a priority. Moreover, the operator must confirm that they have read the new version. This mechanism can be used to generate feedback – for example to the quality department after a customer complaint.

Paper reports: problem and solution

Reports are another area that is covered by the use of paper in a company. These include production, quality, shift, batch and other analyses. In their case, the main challenge is quality as well as regularity and time. They are collected manually – with delays and a considerable risk of human error.

Even despite basic digital implementations, the problem often remains only superficially solved. Duplicate reporting from paper to IT systems (ERP, WMS, CMMS and others) can occur, resulting in communication chaos. Another problem – of high importance in the overall operation of a company! – is the long time it takes for a batch to be released and for documentation to be completed.

Attention should also be drawn to the general difficulty of verifying that the production process has been carried out according to plan.

What is the reality of manual reporting? Standard reports are sometimes very limited:

- production reports contain mostly only the quantities of goods, types of possible defects, data concerning material rejects

- quality reports cover, for example, measurements of samples or general laboratory opinions

- machine reports present the condition of equipment with often inaccurate start-up and stoppage times; worse still, sometimes not all data is entered.

Another example of negligent manual reporting is maintenance records – incorrect fault codes or incorrect start & stop response times are not uncommon.

How does this process generally look in the average company practice? The scenario is usually quite similar. The company organises a daily meeting to summarise the passing day. Participants share data and insights on production volumes or recorded problems and defects. This data is mostly recorded on paper in the form of a summary sheet.

Therefore, the data is:

- generated with delay, not in real time

- not very accurate

- archived manually and in paper form, not digitally

- lacking the possibility of display in the form of various analyses, views and dashboards

How to transfer paper reports into digital form?

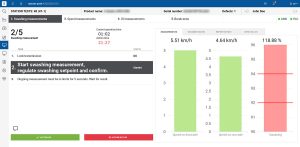

The solution is ANT Production Execution and Paperless technology. It enables automatic retrieval of data from individual machines and then automatic filling in digitalized reports. Using this method, reports and notifications are generated in real time, resulting in better response times.

The benefits of this solution include:

- interface to other information systems

- automatic data exchange thanks to two-way communication

- automated completion of documentation based on reports and data from equipment

- quick access to aggregated and detailed data

- automatic and fast generation of reports

- ease of displaying and creating reports in the form of graphs and histograms (OEE, Pareto, SPC)

- comprehensive step-by-step guide for the operator

- certainty of the correct course of action – ensuring that no stage of production is omitted

Special attention should be paid to the form in which information is presented. MES implementation allows the machine setpoints to be displayed so that the operator can set them based on the data from the ANT screen – only for the production item running. A module for interactive meetings replacing the production boards is also an interesting implementation. This solution allows data to be presented in an automated way and focuses attention on the most up-to-date production results.

What are the benefits of MES in the context of transition from paper to digitalization?

The advantages of the transition can be considered on several levels. The first one is ecology and compliance with the principles of sustainability. By eliminating paper – as the experience of one of our customers shows – around 80,000 pages per month could be saved. Impressive is the fact that it is the equivalent of… 10 trees. A green approach is also important in the context of corporate marketing and PR.

Of course, digitalization as a form of creating a paperless manufacturing environment is also a time-saving measure. Thanks to digitalized shop floor software, employees do not waste time on completing documents and focus more on manufacturing. A faster flow of documents is also a noticeable change.

Another advantage of a paperless system is the elimination of human error. Digital data instead of paper content means always up-to-date documentation and incomparably better production monitoring.

Automatically completed documentation is also appreciated. Based on our customers’ experience, one order in the pharmaceutical industry can contain up to approx. 80 pages. If you look at the aviation industry, it could be as much as 3,600 pages. In addition to material costs, digitalization also means a reduction in expenditure on documentation storage.

An important aspect is real-time operation, which is particularly important when generating production data, for example, to develop machine shop floor plans. Decision-making through notifications takes place immediately – this translates into process continuity.

Products in this Article

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

Paperless Manufacturing

Paperless Manufacturing Streamline your manufacturing with ANT PAPERLESS. Digitize forms, improve communication, and access data securely from anywhere, creating a more efficient and sustainable operation.

Electronic Batch Records (EBR) Software

Electronic Batch Records (EBR) Software: A Digital Solution for Streamlined Batch Management Electronic Batch Records (EBR) software replaces traditional paper-based batch records, offering digital guidance