MES is now undoubtedly the basis of digitalization and the foundation of modern manufacturing activity. In the environment that can be described as Industry 4.0, it is a key factor in determining a possible business success. The reality of Industry 4.0, which – like never before – is analysed and evaluated through the prism of KPIs and all other measurements, requires the adjustment of production processes to MES assumptions.

Get more insight what is Industry 4.0

MES – Manufacturing Execution System – in the context of production management provides solutions that are crucial from the company’s point of view: it streamlines business processes and enables full control of the manufacturing process. However, if we look at the implementation of MES in more detail, what are the benefits of implementing it?

1. Better analysis of the manufacturing process

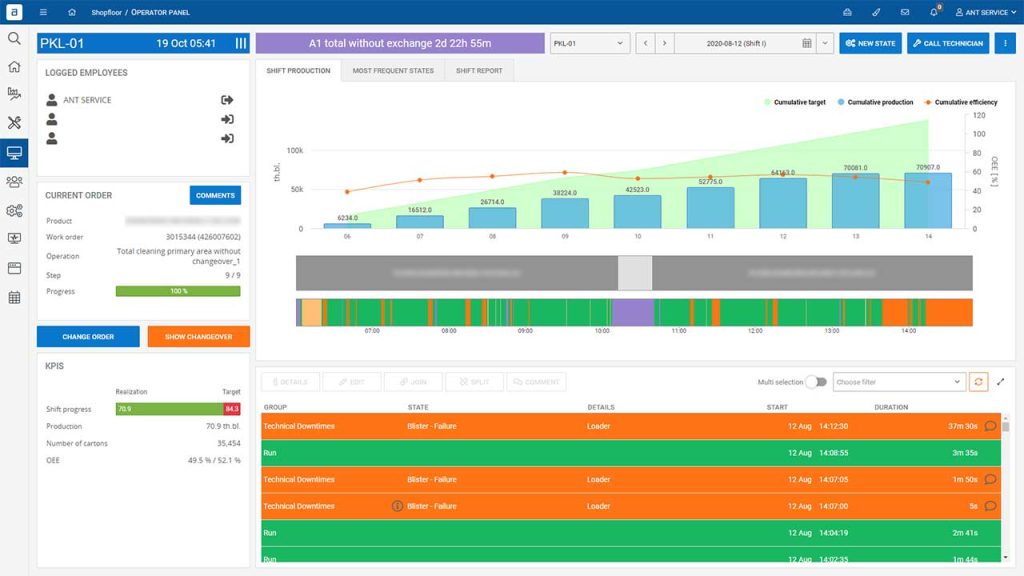

It is also worth looking at MES applications through the prism of data monitoring – OEE trends being of paramount importance for the effectiveness of the activities undertaken. This solution ensures better planning, control and execution of orders.

2. Data provided in real time

Automatic data collection via PLCs, sensors and operator input ensures better assessment of production statuses and progress in real time. Although this advantage is mainly perceived through better, more efficient monitoring of KPIs or assessment of the real OEE value, it can be reduced to the following general observation – MES provides the administrator or manager with a complete overview of all processes occurring in the company.

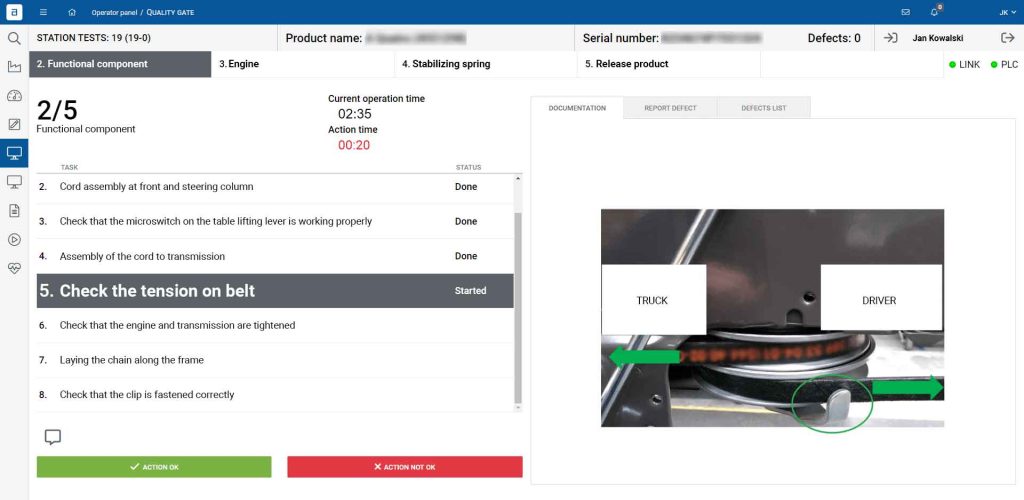

3. Quality under control

However, this is not only about diagnostics but also about prevention. Implementing MES in a business enables early identification of an unstable process. This allows a much faster response to quality results and potential error alerts. On the one hand, this kind of real-time analysis of defects and automation of notifications reduces the risk of spending on faulty product batches. On the other hand, it is always an extremely valuable baggage of experience and knowledge about possible sources of problems.

4. Increased availability of machinery

5. Noticeable increase in performance

- monitoring of changes

- faster production start-up

6. Timely execution of orders

7. Paperless

For years, the excessive amount of paper in circulation – dozens of documents, analyses and certificates – was seen as a necessary evil. MES in business effectively reduces its use. The introduction of digital forms – standard forms and the ability to create your own – as well as other documentation in PDF are some tangible benefits. The main benefit is the reduction of costs and paper expenses. The second one is the ease and speed of updating data and the certainty of its status. MES digitalization instead of the ubiquitous paper also means faster, simpler and more intuitive generation of data reports.

8. Less production waste

MES implementation means significantly more efficient waste management. The system provides real-time notification of defects. The data collected provides better monitoring of progress and volumes. MES also enables error control.

9. Eliminating human error

People can be the weakest link in the production process. MES and automation in general enable better control over the human factor. The added value is a better analysis of the targets expressed in KPIs – the data is more transparent for management and operators. It all boils down to a scheme in which project managers can be sure that specific parameters are set for the machines – without human error or delays.

10. Traceability of processes

11. Shorter reporting time

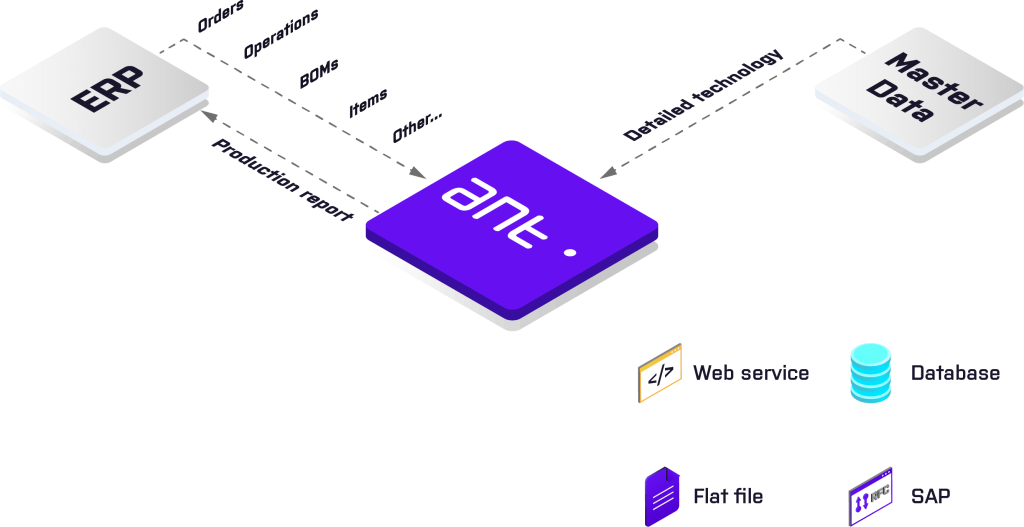

The implementation of MES represents a marked improvement in the efficiency of office work. Implementation combined with the use of other software modules extends the possibilities. It is possible to obtain an automatic interface for other types of software for production – ERP, APS, WMS, CMMS, etc. Fast access to aggregated data and detailed information is also a result of synchronised interfaces.

12. Actual production cost and margin

- time and cost of reworks

- cost of waste

- real costs of energy

13. Quicker induction of new employees

- a set of step-by-step instructions for operators

- easy access to documents

- better communication with management and quality, technology and maintenance departments

MES and implementation – a prospect of benefits

The implementation of MES offers several distinct advantages that have a real positive effect on the company and its production profile. Importantly, the payback process itself is quick. As the analyses show, depending on the size of the company, it takes between 12 and 24 months to achieve ROI.

Products related to this article

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

OEE Performance monitoring

Performance Monitoring (OEE) Connect and gather data from your machines. Schedule a Demo They Trusted Us: Key Benefits OEEincrease ✔️ shorter downtimes ✔️ faster production

Manufacturing Operations Management System (MOM)

Manufacturing Operations Management System (MOM) The most complete manufacturing solution with full support for operations management and a link between industrial automation and business operations